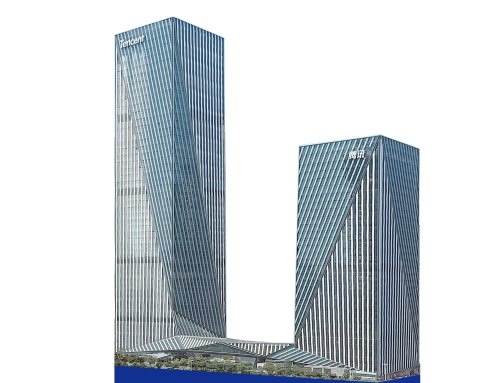

Lenovo Innovation Industrial Park, located in the Tianjin Port Free Trade Zone (Airport Economic Zone) in China, has been fully completed. The project spans an area of 112,000m² and has received a total investment of over RMB ¥1.8 billion. The industrial park comprises two intelligent manufacturing factories, an automated vertical warehouse, a research and development laboratory, and supporting office facilities. The production line includes laptops, desktop computers, servers, workstations, and more.

Since 2021 until project completion, WT China team successfully delivered cost consulting services for the entire project, ensuring effective control over total investment, costs, and engineering quantities.

The project is particularly notable as it represents the highest level of zero-carbon intelligent manufacturing in the ICT industry, with a core focus on “green and zero-carbon + intelligent manufacturing.” Throughout the design, planning, construction, and operation of the industrial park, a total of 90 carbon reduction measures have been implemented, embodying the ESG concept.

The intelligent vertical warehouse features 28,000 storage spaces with a height of 24 meters, achieving over 70% land savings and a 47% cost reduction.

A groundbreaking achievement in the industry, the project introduces a 100% fully automated dark room testing system. Developed by Lenovo Group, this system can test over 150 items across eight categories within two hours, with the entire process conducted in complete darkness. The packaging stage incorporates automated material distribution, ensuring an unmanned and agile production process.

The park also uses photovoltaic power generation, with 30,000m² of distributed photovoltaic panels installed on the roofs of three main production buildings. With an approximate capacity of 3.66MW and an average annual power generation of about 4.47 million kWh, this accounts for 30% of the industrial park’s total area and can reduce carbon emissions by 3,000 tons annually.

Other sustainable features include a rainwater storage system with a capacity of 2,300m³, saving 5% of fresh water annually (equivalent to 3,600 tons), a water recycling system estimated to save 21,600 tons of fresh water per year, and a geothermal fresh air system that achieves a 50% energy saving in the working area each year by using geothermal energy and heat exchangers.

Furthermore, the park’s canteen achieves 100% recycling of kitchen waste, converting it into fertilizer, with a waste reduction rate exceeding 90%.

The project lasted 24 months, enduring seasonal heavy rain and harsh winters in Tianjin. WT China team collaborated closely with the client, delivering work according to target milestones, and adhering to the project’s “dual-carbon” concept. Throughout the service process, we improved work efficiency and quality, promoting approaches such as energy-saving building materials, electromechanical optimisation, and “low-carbon and zero-carbon” that matched with our client’s expectations and enabled the successful completion of the project.

We are excited to witness ongoing transformations of old industries into intelligent industries, and anticipate the future developments that lie ahead.